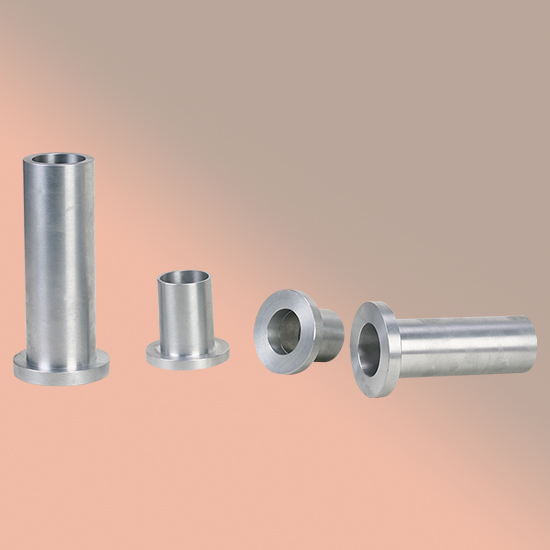

U Bronze Castings

U Bronze is a Zn-Al-Cu-Sn alloy, Silver in colour and has unparalleled bearing properties. U Bronze Bearings can be replaced for Phos. Bronze, Gun Metal, Leaded Bronze, Leaded Tin Bronze, etc to obtain better results at a lower cost.

It has unusual anti-friction properties that brings about a very fine running surface and low temperature, whereby pivots and shafts are protected. Frictional load dissipation of energy is reduced in the use of bushings made of U Bronze, therefore this alloy is suitable and qualifies for bushings for low and high speeds with light and/or heavy loads.

U Bronze can stand extreme conditions of shaft deflections and emergency starting and stopping conditions. It is an ideal bearing material for heavy and light load pressures with low and high surface speeds.

Another major advantage of U Bronze alloy that makes it economical is the fact that it has a specific gravity of 4.8 only as compared to 8.9 of other bronzes, which gives a considerable savings.