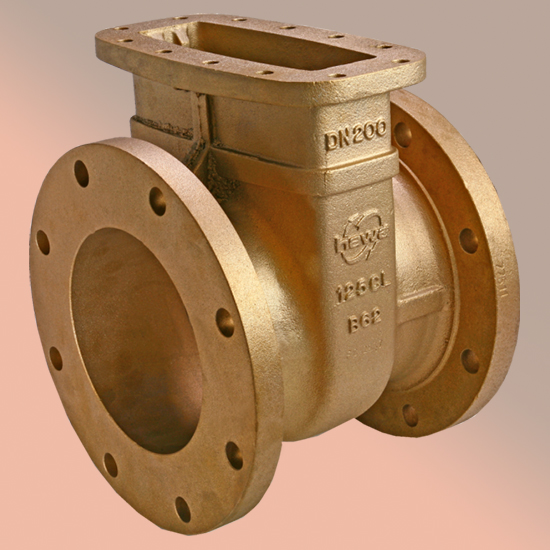

Leaded Tin Bronze (Gun Metal)

Leaded Tin bronzes offer good machinability and retain favorable thermal conductivity and lubricity due to their lead content. The lead content in these alloys is typically between 7 percent and 15 percent. Alloy C93200 is the most common alloy in the family and is used in many bearing applications.

| Available AlloysShow All / Hide All | ||

|---|---|---|

| FAMILY | ALLOY | DESCRIPTION |

| Leaded Tin Bronze | C93200 (SAE 660) | C93200 Bearing Bronze is considered the "standard" bearing material for light duty. The alloy offers a unique combination of easy machining with good strength, hardness and wear resistance. Typical applications include bearings, washers, bushings and automotive fittings. |

| C93200 (SAE 660) | Bearing Bronze is considered the standard bearing material for light duty applications. While it is easily machined, the bronze alloy is hard, strong and resistant to wear. It also conforms well to journal irregularities and is less dependent on lubrication than other alloys. The alloy has reasonable corrosion resistance to seawater and brine. | |